Description

• The machine is made of lightweight aluminum alloy material, with small size, light weight per unit. • Ordinary three-phase power supply, uniform temperature of hot plate, water pressure system supplies (1.0~2.0mpa) uniform pressure. • Equipped with a lightweight fully automatic LCD digital display temperature control box, the connection between the temperature control box and the host is completed by an integrated plug-in and a multi-core cable, easy to operate and reliable. • It has the characteristics of fast heating, uniform temperature, and high thermal efficiency. It is an ideal bonding equipment for rubber belt joints of conveying machinery. • The quality of the tape joint directly affects the working effectiveness and service life of the tape, especially the current long-distance and high-strength conveyor belts.

Use

• Rubber conveyor belt vulcanizing machine are used for joint rubber belts such as canvas rubber belts, nylon belts and steel wire core belts etc. • Can also be used for joining-up the special purpose rubber belts such as the flame�retardant rubber belts and anti-corrosive rubber belts etc. • It can be widely used in the enterprises such as metallurgical plants, mines, electric power plants and docks etc, and can also be suitable for the ambient without explosive gases and the places without metal corrosive harmful gases.

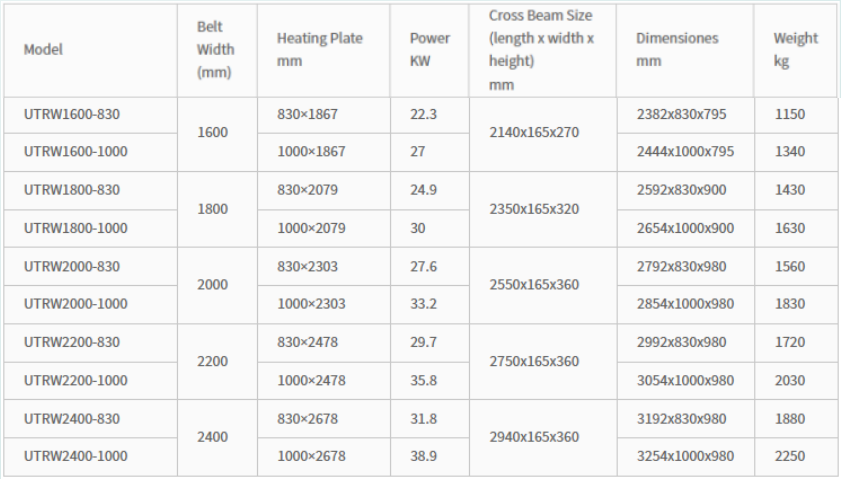

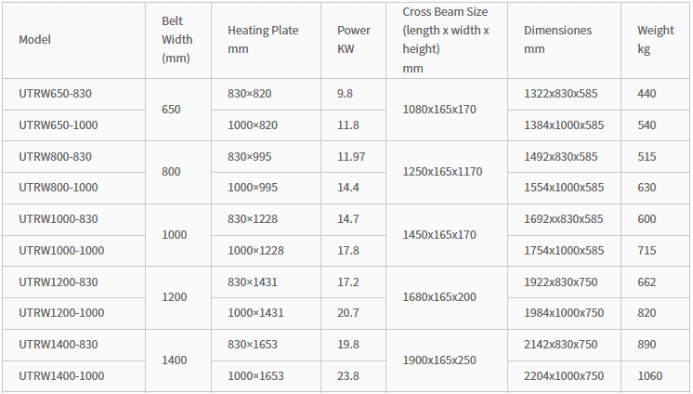

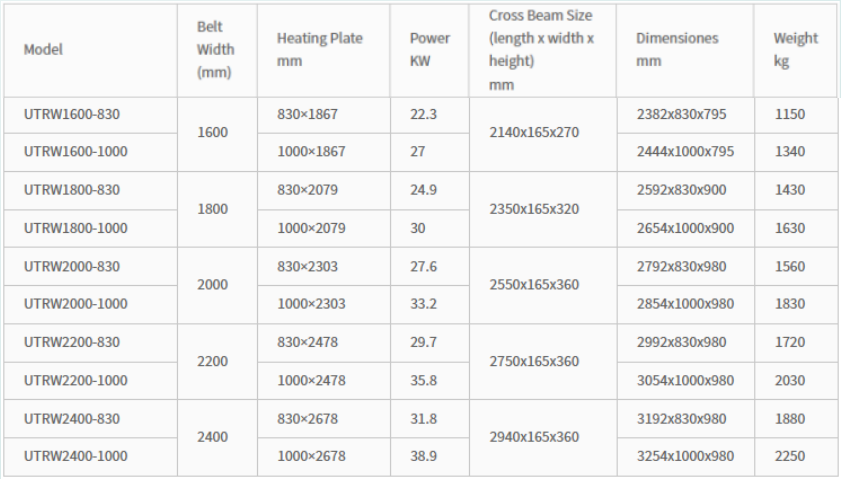

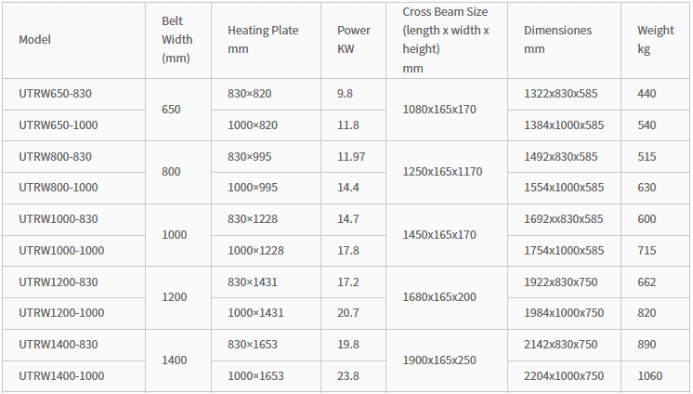

Technical Parameters

1. Vulcanizing pressure: 1.5 MPa (15 kg / cm2) 2. Vulcanizing temperature: 145℃ (adjustable) 3. Temperature difference on the wording surface: ±5℃ 4. Temperature-rising time (from normal temperature to vulcanizing temperature): no more than 35 min 5. Power voltage: 380V / 50 Hz (3-phase 4- wire), or 660 V; 6. Output voltage of electric control box: 380V / 50 Hz; 220V / 50 Hz (standby); 7. Output current of electric control box: 60A 8. Adjusting range of temperature from temperature regulator: 0~300℃ 9. Adjusting range of time from timer: 0~99 min 10. Gap between upper heating plate & lower heating plate after have been pressurized: no more than 0.5 mm

Technical Parameters

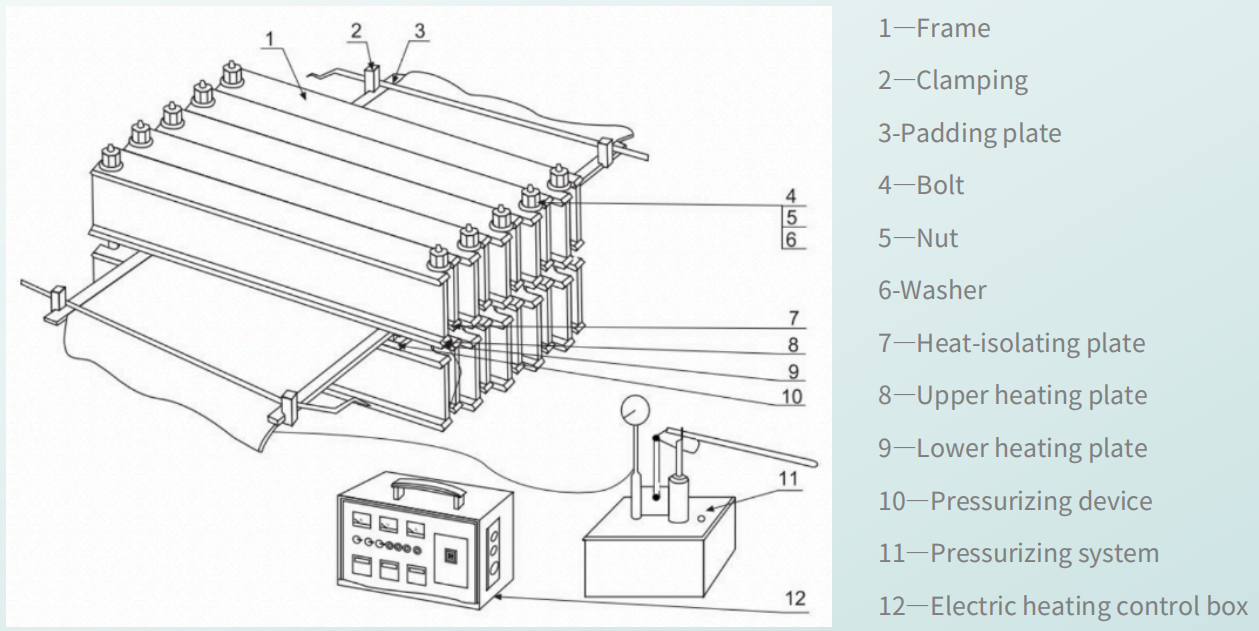

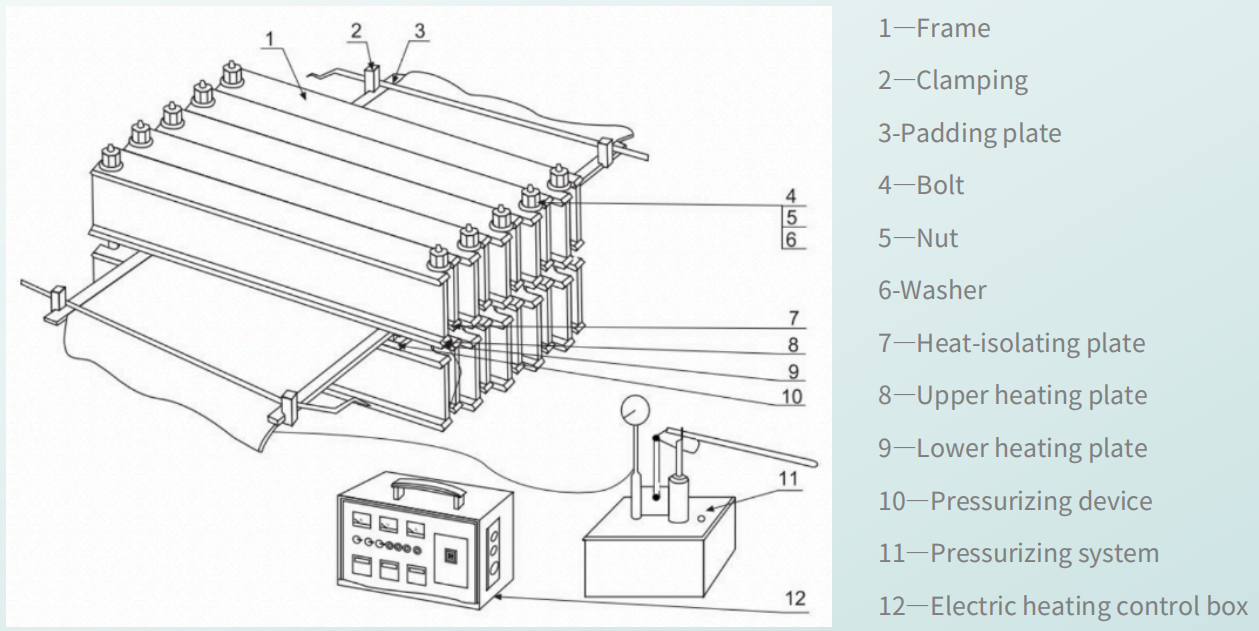

Key Components Details

Auto controller with cables

• Include 2 temperature controllers, 1pc timer, 2 pcs amperemeters and one pc voltmeter

• Dual Omron or SHIMADEN digital temperature control and indication

• The same standard as Almex, easy exchange by your old Almex control system. More flexible and save cost.

• Accurate temperature and read out, CE approved electric components.